Welcome To Your Solution

We understand the different challenges and issues that you need to manage day to day, year to year to ensure consistent, safe, profitable production.

Finding the right solution to these issues can be difficult without over complicating, but yet getting the desired result your after for greater sustainable production.

Solutions

Fats, Oils, Greases (FOGs)

Fats, Oils, Greases (FOGs)

Fats, Oils, Greases (FOGs)

Buildup of fats, oils and greases (FOGs) and filamentous bacteria cause almost 70% of blocked drains, pipes and sewers with significant infrastructure damage following this.

Emulsifiers may temporarily break FOGs down, but this simply transfers the problem downstream – and even into the wider environment.

Our technology is a systemic effect and treats FOG's at the source and throughout your whole system.

Noxious Gases

Fats, Oils, Greases (FOGs)

Fats, Oils, Greases (FOGs)

Noxious gases such as hydrogen sulfide (H2S), ammonia, methane etc are responsible for odour and corrosion in wastewater infrastructure.Having a big sale, on-site celebrity, or other event? Be sure to announce it so everybody knows and gets excited about it.

We can eliminate your noxious gas issues by using a combination of aeration with microbubble technology, bio-catalytic breakdown and removal of bio-film - resulting in a permanent solution for you.

Biofilm

Fats, Oils, Greases (FOGs)

Biofilm

Bio-films create major problems for many industries. In wet areas of machinery, pipes, irrigation lines and belts causing black stains, blockages odour, and machine downtime's, resulting in low productivity.

Biocides, Chlorines & Peroxides are industries go to chemicals for some control, however, they often create a toxic stream causing significant issues.

The Patented organocatalyst, EcoSystem Plus™, degrade lipids, proteins and exopolysaccharides within the structural network of bio-film formed by harmful microorganisms. The organocatalyst quickly removes existing slime and prevents further slime redepositing.

Sludge

Bio-Remediation

Biofilm

The buildup of sludge in lagoons, ponds and wastewater treatment plants contributes negatively to the overall water quality. Sludge buildup unnecessarily takes up valuable space in your dam, creates offensive odours, can be extremely costly to remove and supports pathogen activity.

Combining aeration process with EcoSystem Plus enhances the breakdown of the accumulated organic sludge.

Bio-Remediation

Bio-Remediation

Bio-Remediation

Bio-remediation is a process used to treat contaminated media, including water, soil and subsurface material, by altering environmental conditions to stimulate growth of microorganisms and degrade the target pollutants.

Through a systematic, controlled process and product technology, EcoCatalysts can offer bio-remediation solutions for Hydrocarbon contamination and Agricultural contamination.

Water Quality

Bio-Remediation

Bio-Remediation

Declining water quality is an acute problem around the world caused by issues including: agricultural runoff and industrial waste water.

This issue is prominent in areas with large industrial production and inadequate waste water treatment. High levels of ammonia, phosphates and TSS is often caused by waste discharges or soil erosion.

EcoCatalysts can remove ammonia and phosphorus and defeat algae by competitive exclusion. The technology enhances consumption of TSS and reduce accumulated sludge.

Aeration

Aquaculture Water Quality

Aquaculture Water Quality

Anaerobic (devoid of oxygen) water conditions begin to develop in deeper water resulting in the naturally occurring aerobic microbes being unable to perform beneficial tasks such as waste digestion or water purification.

In time, these conditions lead to poor water quality, unsightly algae blooms, accumulation of sludge and buildup of gases.

EcoCataylsts’ technology revolves around creating an environment with high levels of dissolved oxygen and oxygen transfer.

Aquaculture Water Quality

Aquaculture Water Quality

Aquaculture Water Quality

Poor quality water in the Aquaculture industry can cause considerable production losses. poor feed conversion, disease, lower growth rates as well as environmental issues of odour and sludge build up.

Our technology improves water quality, clarity, reduces chemical usage, reduction of sulfides, ammonia, phosphorus and nitrite and improves fish mortality in aquaculture operations. It provides very high oxygen transfer characteristics, and accumulation of greater dissolved oxygen in water bodies.

Technology Economics

Economic Analysis

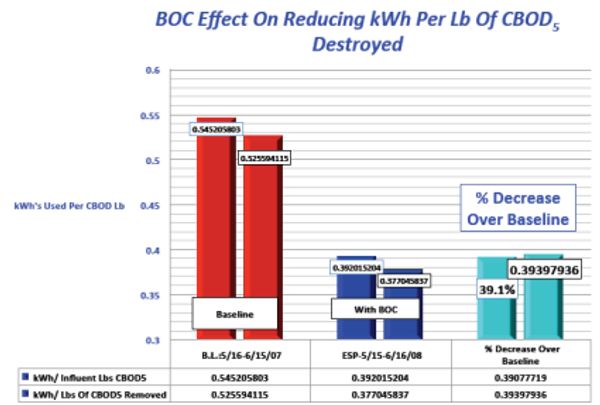

Our Organocatalyst Technology offer wastewater operators a viable and rapid solution that transforms the entire biological processing parameters of both the collection system and wastewater treatment facility, optimizing the entire system-wide operations.

Eliminating odors, reducing energy consumption, and increasing renewable energy yields are all benefits that are brought to operators by the EcoCatalysts advanced bio-catalytic products.

Every wastewater system’s economic model will be based upon their specific costs of odor and corrosion prevention, energy usage and biosolids disposal. Off-setting capital improvements and plant expansions can save municipalities and companies substantial investment dollars. Improving discharges benefits our environment and regulatory compliance.

Our Organocatalyst Technology of bio-catalytic products can be an integral part of facilities’ upgrades and maintenance programs. Cooperative relationships with engineering design and build installations can provide improvements to the payback analysis.

Learn More

Learn more on how Organocatalyst Technology can assist you create a positive economic analysis through these case studies.

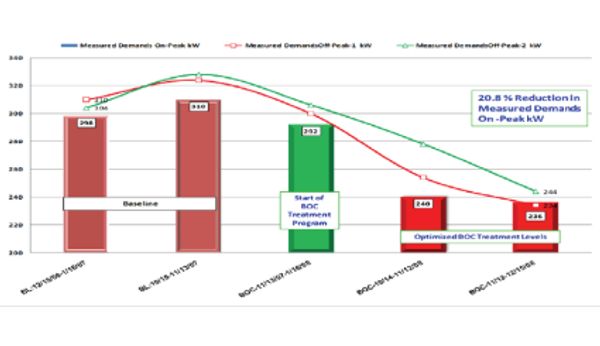

Reduction of Electrical Costs

Reduction Of Electrical Costs

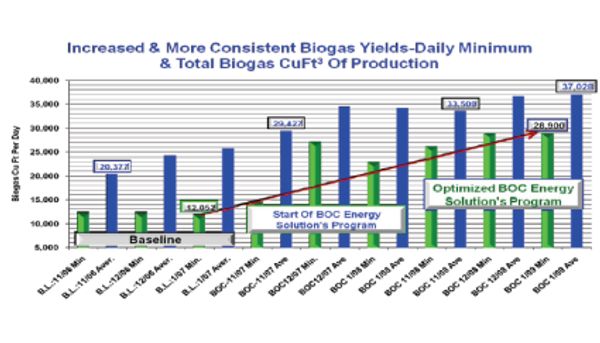

Methane Yield Improvements

Your Solutions

Fats, Oils, Greases (FOGs)

Buildup of fats, oils and greases (FOGs) and filamentous bacteria cause almost 70% of blocked drains, pipes and sewers with significant infrastructure damage following this.

Emulsifiers may temporarily break FOGs down, but this simply transfers the problem downstream – and even into the wider environment.

Your Solution

Our solution for Fats, Oils and Grease buildup is a two step process. Using our bio-organic catalyst technology we breakdown the FOGs blocking your pipes, sewers, wet wells and pump stations into fatty acid components. Then with microbubble technology which create an aerobic environment which causes microbes to consume these fatty acids. Our solution is non caustic containing neither bacteria nor active enzymes – which makes it completely harmless to the environment, complementing virtually all microbiological systems and chemical purification processes, enhancing their efficiency.

Your Results

- Rapid solubilisation of Fats, Oils and Grease

- Elimination of hazardous gases and noxious odours

- Greatly increased dissolved oxygen

- No more membrane fouling

What makes us different?

- We permanently eliminate Fats,Oils and Grease from your drains, sewer pipes, wet wells and pump stations

- Full installation service included

- Cut grease cap levels by 60% in only four days

- 100% natural non caustic solution

- Prevent Fats, Oils and Grease from forming downstream

Industries where it is used:

- Municipal wastewater

- Meat and Smallgoods

- Dairy

Products

- EcoSystem Plus

- Small scale Aerator

- Pump Station Installation System

OH&S statement

Our solution will assist your OH&S risk by

- Removing slippery services

- Reducing the frequency of operators having to access the pump station

Noxious Gases

Noxious gases such as hydrogen sulfide (H2S), ammonia, methane etc are responsible for odour and corrosion in wastewater infrastructure.

As a result, a build up of these noxious gases can be extremely costly expense to your business. Removal of H2S from your wastewater is necessary to protect your assets and reduce maintenance costs.

Your Solution:

We effectively eliminate your noxious gas issues by using a combination of aeration with microbubble technology, bio-catalytic breakdown and removal of bio-film - resulting in a permanent solution for you. The effect of this is a highly aerobic environment and hostile environment for H2S forming bacteria within the pump station and surrounding reticulation system.

Your Results:

- Increased dissolved oxygen through microbubble technology

- Eliminate noxious gases

- Reduce maintenance costs and improve asset protection

What makes us different?

- Whole system corrosion protection

- We prevent H2S instead of simply curing the issue

- Treatment plant receives improved effluent

- We offer a permanent solution by removing the bio-film

- Don’t create downstream sludge problems

Industries where it is used:

- Sewerage Treatment Plant

- Underground Mine Sites

- Sewerage Reticulation Systems

Products:

- Aerators

- EcoSystem Plus

- Pump Station Installation System

OH&S statement

Our solution will assist your OH&S risk by

- Reducing the frequency of needs operators to access the pump station

- Removing explosion hazard

- Removing toxic gases which are harmful to operators and the public

Bio-Film

A biofilm comprises any syntrophic consortium of microorganisms in which cells stick to each other and often also to a surface. These adherent cells become embedded within a slimy extracellular matrix that is composed of extracellular polymeric substances (EPS)

In industrial environments, bio-films are a force to be reckoned with. Since most production facilities use water to cool equipment or depend on pipes to transport resources, there's a substantial risk of developing bio-films. According to one estimate, bio-films cause well over a billion dollars' worth of damage every year in industrial settings, affecting human health and companies' abilities to manufacture their products efficiently [source: Montana State University CBE; Sturman]

Biocides, Chlorines & Peroxides are industries go to chemicals for some control, however, they often create a toxic stream causing significant issues.

Your Solution:

The Patented organocatalyst, EcoSystem Plus™, degrade lipids, proteins and exopolysaccharides within the structural network of bio-film formed by harmful microorganisms. The organocatalyst quickly removes existing slime and prevents further slime redepositing.

Your Results:

- Elimination of microscopic bio-film growth

- Increased dissolved oxygen through microbubble technology

- Are completely non-toxic, biodegradable, and non-allergenic.

- Eliminate odour

- Reduce maintenance costs and improve asset protection

What makes us different?

- Whole system removal

- Once bio-film removed will not come back with low maintenance doses.

- Don’t create downstream problems

Sludge

Bio-Remediation

The buildup of sludge in lagoons, ponds and wastewater treatment plants contributes negatively to the overall water quality. Sludge buildup unnecessarily takes up valuable space in your dam, creates offensive odours, can be extremely costly to remove and supports pathogen activity

Your Solution:

Through the use of aerators with microbubble technology we cause the sludge to be aerobic and in turn eliminate the offensive odours. The act of aeration exposes the sludge buildup to a very high population of anoxic microorganisms which rapidly consume this layer of sludge and improve the water quality. Combining this aeration process with our products EcoSystem Plus TM and/or Waste and Sludge Reducer, enhances the breakdown of the accumulated organic sludge.

Your Results

- Increased dissolved oxygen

- Elimination of organic sludge

- Improved water quality

- Avoid the need to dig and dump

- Increased pond/lake capacity

What makes us different?

- In-situ solution

- Beneficial microbes

- Bio-catalysts for oxygen transfer

- American made

- High efficiency aeration

Industries where it is used:

- Aquaculture

- Wastewater Treatment Plant

- Lagoons and Ponds

Products

- EcoSystem Plus

- Aerators

- Waste and Sludge Reducer™

OH&S statement

Our solution will assist your OH&S risk by

- Removing the need for heavy machinery

- Reducing harmful pathogens

Bio-Remediation

Bio-Remediation

Bio-Remediation

EcoCatalysts can offer bio-remediation solutions for Hydrocarbon contamination and Agricultural contamination.

Your Solution:

We use bio-catalysts to breakdown the contaminants and stimulate microbiology to consume the contaminants. The end result of this process is breaking these contaminants down into nonhazardous components.

Your Results:

- Fast Total Petroleum Hydrocarbon and BTEX remediation for soil at a rate of 5% per day

- Immediate suppression of VOCs and other organic odour

- Rapidly raise a flashpoint and lower explosion limit for confined space activity

- Non hazardous to marine life. Cleans rocks and beaches.

- Recirculation oxidation systems treat contaminated groundwater, streams and ponds

What makes us different?

- Practical and cost saving

- We do this process in-situ

- We can remediate soil, air, water and salt water

- Our product is safe with all aquatic life

- We are remediating odours as opposed to masking them

Industries where it is used:

- Transportation

- Oil and Gas

- Mining

- Agriculture

OH&S statement:

Our solution will assist your OH&S risk by

- Reducing cancer causing agents

- Reducing explosion and fire hazards

Water Quality

Bio-Remediation

Bio-Remediation

Declining water quality is an acute problem around the world caused by issues including: agricultural runoff and industrial waste water.

Eutrophication also significantly reduces your water quality through triggering excessive growth of algae, including blue-green algae which presents a high risk in waterways. Industries including: piggeries, poultry and dairy farms are potential sources of nutrient runoff or leaching increasing eutrophication

Your Solution:

Using beneficial microbes we remove ammonia and phosphorus and defeat algae by competitive exclusion. The microbes also consume TSS and reduce accumulated sludge.

Your Results:

- Eliminate algae blooms

- Increase dissolved oxygen

- Eliminate stratification and eutrophication issues

- Reduce excess odours

- Eliminate fish kills

What makes us different?

- Easy application

- Biological product that provides long lasting results

- Our product is safe with all aquatic life

- We are remediating odours as opposed to masking them

Industries where it is used:

- Aquaculture

- Recreational lakes and ponds

- Wastewater treatment plants

- Golf Courses

- Residential lakes

- Nurseries

- Agribusiness

Products

- EcoSystem Plus

- Aerators

- Waste and Sludge Reducer™

OH&S statement:

Our solution will assist your OH&S risk by

- Controlling harmful pathogens

- Providing a non-chemical solution with no algaecides

- Improving your water quality

Aeration

Aquaculture Water Quality

Aquaculture Water Quality

Anaerobic (devoid of oxygen) water conditions begin to develop in deeper water resulting in the naturally occurring aerobic microbes being unable to perform beneficial tasks such as waste digestion or water purification.

In time, these conditions lead to poor water quality, unsightly algae blooms, accumulation of sludge and buildup of gases.

The overriding principle in EcoCataylsts’ technology revolves around creating an environment with high levels of dissolved oxygen and oxygen transfer. We provide aerators for sub-surface aeration as well as pump station aerators. Our aeration systems with microbubble technology create aerobic conditions in your water to significantly increase dissolved oxygen while eliminating water stratification and nitrification issues.

Your Results:

- Decrease electricity costs

- Increase and maintain dissolved oxygen

- Reduce bottom sludge

- Decrease offensive odours

- Improved aesthetic value

What mak us different?

- Different options to suit your needs (230 volt aerators or solar aerators)

- Sub-surface and pump station aerators

- Extremely quiet

- American & Australian made

- High efficiency

Industries where it is used:

- Aquaculture

- Recreational lakes and ponds

- Wastewater treatment plants

- Golf Courses

- Residential lakes

- Nurseries

- Agribusiness

Products

- EcoSystem Plus

- Aerators both 240v and Solar

Aquaculture Water Quality

Aquaculture Water Quality

Aquaculture Water Quality

Poor quality water in the Aquaculture industry can cause considerable production losses, poor feed conversion, disease, lower growth rates as well as environmental issues of odour and sludge build up.

Our bio-catalytic composition transforms water care with a new technical breakthrough that addresses the key challenges of maintaining Aquaculture water system quality and clarity, specifically the management of the challenges of organic loading's.

The technology works through the power of microbubble oxygen transfer, allowing higher aerobic levels within the water and reducing biological film growth and mineralisation.

It enhances the effects of oxidizing, sanitizing, and anti-scaling chemical agents, while reducing the quantities required. It safeguards equipment and improves water discharges.

Your Results:

- Provides the highest level of water quality.

- Reduces chemical usage.

- Biological reduction of sulfides, ammonia, phosphorus and nitrite

- Reduced environmental stress on stocks

- Reduced turbidity

- Reduced / eliminated phytoplankton growth.

- Reduced bacterial growth (Enhanced bio-security)

- Eliminates fouling of filters.

What makes us different?

- Improves water quality and personnel safety.

- It provides very high oxygen transfer characteristics, and accumulation of greater dissolved oxygen in water bodies.

- Is compatible with all sanitizing chemicals and filtration systems.

Products

- EcoSystem Plus

- Aerators

.

Video

This video shows the ability of BOC to increase Dissolved Oxygen of water. A great advantage across many industries.